G40 Galvanized Coil

Category:

Galvanized Steel Coil

Chat with us now for a quick response.

Get expert sales advice within 12 hours.

Keyword:

G40 Galvanized Coil

PRODUCT DETAILS

G40 Galvanized Coil Description

The coating designation G40 represents the type of coating and the weight of the applied coating. The letter "G" indicates that the coating is galvanized, meaning zinc-based. Meanwhile, the number "40" represents the weight of zinc on the surface of the steel sheet.

Galvanized steel coils are covered with a zinc coating to provide corrosion resistance. G40 galvanized steel coil is a galvanized layer name or A653 standard specification specified in the hot-dip coating process galvanized (galvanized) or zinc-iron alloy (galvanized) steel sheet requirements. The G40 protective coating prevents moisture from reaching the steel structure, thereby improving the corrosion resistance of the steel. This can extend the life expectancy of the steel. G40 is the average coat weight and therefore provides moderate protection.

Scope of Application

Galvanizing products are widely used in industry, agriculture, animal husbandry and fishery, energy, transportation, chemical industry, light industry, home appliances, construction, communications, national defense and other fields.

Product Parameters

|

Product Name |

G40 Galvanized Coil |

|

Thickness |

0.12mm-3.5mm |

|

Width |

600mm-1500mm |

|

Length |

508mm/610mm, Support Customization |

|

Standard |

AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, etc. |

|

Zinc Layer |

Hot Galvanizing: 60-275g/m² |

|

Pre-galvanized: 80-275g/m² |

Chemical Composition

|

Standard |

Grade |

C |

Si |

Mn |

P |

S |

Ti |

|

Forcold Forming Chinese Standard |

DX51D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

DX52D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

DX53D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

DX54D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

DX56D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

DX57D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

Forcold Forming Japanese Standard |

SGCC |

0.15 |

0.50 |

0.80 |

0.050 |

0.030 |

0.025 |

|

SGCD1 |

0.12 |

0.50 |

0.60 |

0.040 |

0.030 |

0.025 |

|

|

SGCD3 |

0.08 |

0.50 |

0.45 |

0.030 |

0.030 |

0.025 |

|

|

SGCD4 |

0.06 |

0.50 |

0.45 |

0.030 |

0.030 |

0.025 |

|

|

For Structure Japanese Standard |

SGC340 |

0.25 |

0.50 |

1.70 |

0.200 |

0.035 |

0.025 |

|

SGC400 |

0.25 |

0.50 |

1.70 |

0.200 |

0.035 |

0.150 |

|

|

SGC490 |

0.30 |

0.50 |

2.00 |

0.200 |

0.035 |

0.025 |

|

|

SGC510 |

0.30 |

0.50 |

2.50 |

0.200 |

0.035 |

0.025 |

|

|

For Structure AISI Standard |

S220GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.025 |

|

S250GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.025 |

|

|

S280GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.025 |

|

|

S320GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.025 |

|

|

S350GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.150 |

|

|

S550GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.150 |

Mechanical Properties

|

Grade |

Yield Strength MPa≥ |

Tensile Strength MPa≥ |

Elongation A%≥ |

|

DX51D Z/ZM/AZ/AM |

240-380 |

270-500 |

22 |

|

DX52D Z/ZM/AZ/AM |

140-300 |

270-420 |

26 |

|

DX53D Z/ZM/AZ/AM |

140-260 |

270-380 |

30 |

|

DX54D Z/ZM/AZ/AM |

120-220 |

260-350 |

36 |

|

S220GD Z/ZM/AM |

220 |

300 |

20 |

|

S250GD Z/ZM/AZ/AM |

250 |

330 |

19 |

|

S280GD Z/ZM/AM |

280 |

360 |

18 |

|

S300GD A/AM |

300 |

380 |

18 |

|

S320GD Z/ZM/AM |

320 |

390 |

17 |

|

S350GD Z/ZM/AZ/AM |

350 |

420 |

16 |

|

S450GD A/AM |

450 |

480 |

15 |

|

S550GD Z/ZM/AZ/AM |

550 |

550 |

- |

Galvanized Surface Selection

|

Zero Spangle |

Minimized Spangle |

Normal Spangle |

Large Spangle |

|

|

|

|

|

|

Use of The Environment |

Recommended Zinc Thickness |

|

Indoor Use |

Z10 or Z12 (100g/㎡or 120g/㎡) |

|

Suburbs |

Z20 and Painting (200g/㎡) |

|

Urban or Industrial Area |

Z27 (270g/㎡) or G90 (US Standard) and painted |

|

Coastal Area |

Thicker than Z27 (270g/㎡) or G90 (US Standard) and painted |

|

Punch or Deep Drawing Application |

Thicker than Z27 (270grams/㎡) or G90 (US Standard) avoid coating peeling after stamping |

|

Surface Treatment Type |

Code |

Features |

|

Chromic Acid Treatment |

C |

Good corrosion resistance, suitable for bare state |

|

Chromic Acid Treatment+Oiling |

S |

Good corrosion resistance |

|

Phosphoric Acid Treatment (Including Sealing Treatment) |

P |

Have a certain corrosion resistance, good paint performance |

|

Phosphoric Acid Treatment (Including Sealing Treatment)+Oiling |

Q |

Has a certain corrosion resistance, good paint performance, prevent rust during transportation and storage |

|

Phosphoric Acid Treatment (Excluding Sealing Treatment) |

T |

Have a certain corrosion resistance, good paint performance |

|

Phosphoric Acid Treatment (Excluding Sealing Treatment)+Oiling |

V |

Has a certain corrosion resistance, good paint performance, and prevent rust |

|

Oiling |

O |

Prevent rust during transportation and storage |

|

No Treatment |

M |

Suitable for immediate painting |

Material Comparison

|

Chinese Standard |

Japan Standard |

European Standard |

|

DX51D Z/DC51D Z (CR) |

SGCC |

DX51D Z |

|

DX52D Z/DC52D Z |

SGCD1 |

DX52D With |

|

DX53D Z/DC53D Z/DX54D Z/DC54D Z |

SGCD2/SGCD3 |

DX53D Z/DX54D Z |

|

S220/250/280/320/350/550GD Z |

SGC340/400/440/490/570 |

S220/250/280/320/350GD Z |

|

DX51D Z/DD51D Z (HR) |

SGHC |

DX51D Z |

Packing and delivery

Our annual sales are 8,000 tons. It is the top steel service provider and steel solution provider in the region. The company has a powerful sales team to provide customers with comprehensive technical support, pre -sales service and comprehensive after -sales service. The entire perfect treatment and sales process is our quality assurance.

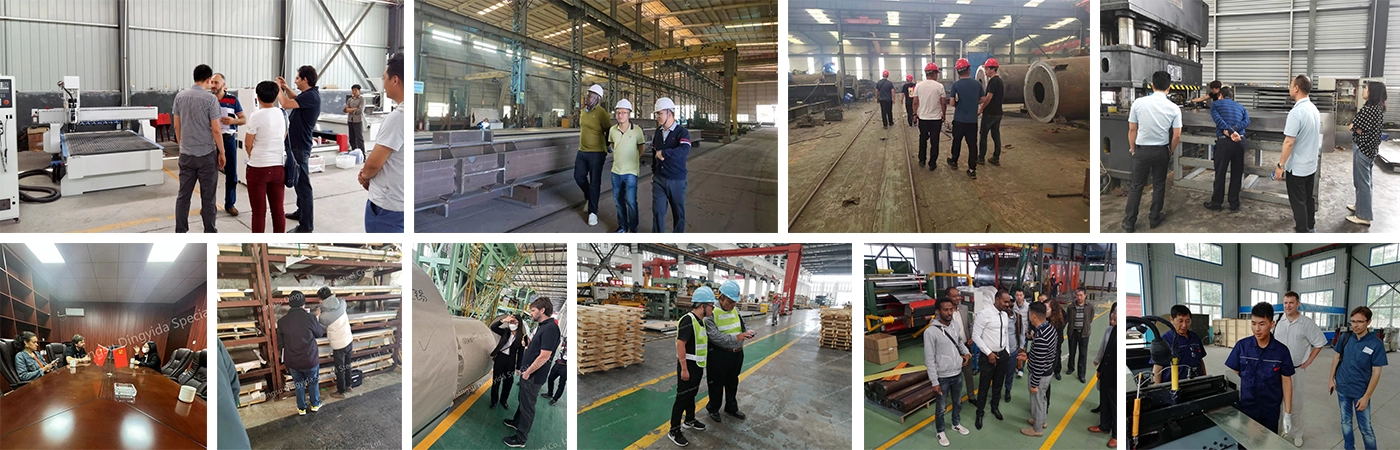

FACTORY

CUSTOMER VISIT

Customer communication

Partner

COMMON PROBLEM

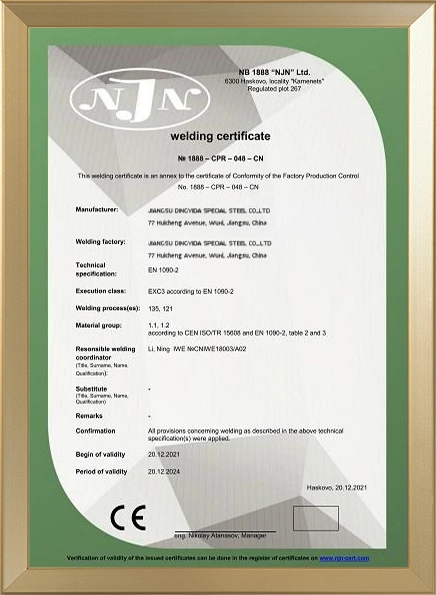

OUR HONOR

APPLICATION SCENARIOS

Oil field

Aircraft manufacturing

Train manufacturing

Ship manufacturing

Power industry

Construction industry

GET A FREE QUOTE

RELATED PRODUCTS