Galvalume Steel Coil

Category:

Galvalume Steel Coil

Chat with us now for a quick response.

Get expert sales advice within 12 hours.

Keyword:

Galvalume Steel Coil

PRODUCT DETAILS

Galvalume Steel Coil Description

Galvanized zinc coil is based on cold-rolled steel plate, which is solidified by 55% aluminum, 43.4 zinc and 1.6 silicon at 600 ℃. It combines the physical protection and high durability of aluminum with the electrochemical protection of zinc. Also known as aluminized zinc steel coil.

The production process of aluminum zinc plating is as follows:

Uncoiling-cleaning-annealing-zinc pot-cooling-air knife-straightening-post-treatment-coiling

Heat Reflection

People use it as a thermal insulation material, and its thermal reflectivity is up to twice that of galvanized steel.

Heat Resistance

Galvanized steel coil has good heat resistance and can withstand high temperatures above 300°C, which is very similar to the oxidation resistance of aluminized steel at high temperatures. Commonly used in chimney tubes, ovens, illuminators, fluorescent lampshades, etc.

Corrosion Resistance

The key to the corrosion resistance of aluminized zinc steel coil is the protective performance of aluminum. Once the zinc is worn, the aluminum forms a dense layer of aluminum oxide, preventing further internal corrosion.

Economy

The density of 55% AL-Zn is smaller than that of Zn. Therefore, when the coating weight and thickness are the same, the area of the aluminum-zinc plated steel sheet is 3% larger than that of the galvanized steel sheet.

Easy to Paint

The coating material on the aluminized zinc steel plate has excellent adhesion, and can be directly coated with tar on advertising boards and common plates without pretreatment such as weathering.

Scope of Application

Construction industry: such as roof, internal and external wall panels, sound insulation walls, pipes, garages, etc.

Automotive industry: such as mufflers, exhaust pipes, wiper accessories, fuel tanks, truck containers, etc.

Household appliances: such as refrigerator backplane, air conditioner, microwave oven, LED backlight, electric cabinet, etc

Agricultural use: such as greenhouse, granary, pig farm, chicken coop, etc

Other industries: such as heat exchangers, dryers, etc.

Product Parameters

|

Product Name |

Galvalume Steel Coil |

|

Thickness |

0.12mm-6.00mm |

|

Width |

600mm-1500mm |

|

Length |

1m-12m, Support Customization |

|

Standard |

AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, etc. |

|

Thickness of Aluminum Zinc Coating |

30-185g/m² |

|

Content of Al-Zn Coating |

Al: 55%, Zn: 43.5%, Si: 1.5% |

Chemical Composition

|

Al |

Zn |

Si |

Fe |

Cu |

Cd |

Pb |

Sn |

Ni |

Close Cr |

|

55-58 |

41-43 |

1.5-2 |

0.25 |

0.03 |

0.05 |

0.01 |

0.05 |

0.05 |

0.05 |

Mechanical Properties

|

Grade |

Yield Strength MPa≥ |

Tensile Strength MPa≥ |

Elongation A%≥ |

|

DX51D Z/ZM/AZ/AM |

240-380 |

270-500 |

22 |

|

DX52D Z/ZM/AZ/AM |

140-300 |

270-420 |

26 |

|

DX53D Z/ZM/AZ/AM |

140-260 |

270-380 |

30 |

|

DX54D Z/ZM/AZ/AM |

120-220 |

260-350 |

36 |

|

S220GD Z/ZM/AM |

220 |

300 |

20 |

|

S250GD Z/ZM/AZ/AM |

250 |

330 |

19 |

|

S280GD Z/ZM/AM |

280 |

360 |

18 |

|

S300GD A/AM |

300 |

380 |

18 |

|

S320GD Z/ZM/AM |

320 |

390 |

17 |

|

S350GD Z/ZM/AZ/AM |

350 |

420 |

16 |

|

S450GD A/AM |

450 |

480 |

15 |

|

S550GD Z/ZM/AZ/AM |

550 |

550 |

- |

Galvanized Surface Selection

|

Zero Spangle |

Minimized Spangle |

Normal Spangle |

Large Spangle |

|

|

|

|

|

|

Type of Coating |

Recommended Coating Weight |

|

Aluminum-zinc Alloy |

30/40/50/60/75/90/100/150 |

|

A: Coating quality50g/㎡,approximately equal to the coating thickness13.3pm |

|

|

Project |

Classification |

Symbol |

|

Type of Coating |

Aluminum-zinc Alloy |

AZ |

|

Surface Finish |

Conventional Sequins |

R |

|

Minimize Sequins |

M |

|

|

Skin Through |

S |

|

|

Surface Treatment |

Chromate Passivation |

c |

|

Non-chromate Passivation |

C5 |

|

|

Chromate Passivationoiling |

CO |

|

|

Chromium-free Passivationoiling |

CO5 |

|

|

Anti-fingerprint |

N |

|

|

Chromate-free/Anti-fingerprint |

N5 |

|

|

No chromate high weather resistance fingerprint |

NW |

|

|

Oil filling |

0 |

|

|

No treatment |

U |

Material Comparison

|

Chinese Standard |

European Standards |

American Standard |

Japanese Standard |

|

DC51D+AZ |

DX51D+AZ |

CS Type B, Type C |

SGLCC |

|

DC52D+AZ |

DX52D+AZ |

DS |

SGLCD |

|

S250GD+AZ |

S250GD+AZ |

255 |

- |

|

S300GD+AZ |

- |

- |

- |

|

S350GD+AZ |

S350GD+AZ |

345 |

Class1 SGLC490 |

|

S550GD+AZ |

S550GD+AZ |

550 |

SGLC570 |

Packing and delivery

Our annual sales are 8,000 tons. It is the top steel service provider and steel solution provider in the region. The company has a powerful sales team to provide customers with comprehensive technical support, pre -sales service and comprehensive after -sales service. The entire perfect treatment and sales process is our quality assurance.

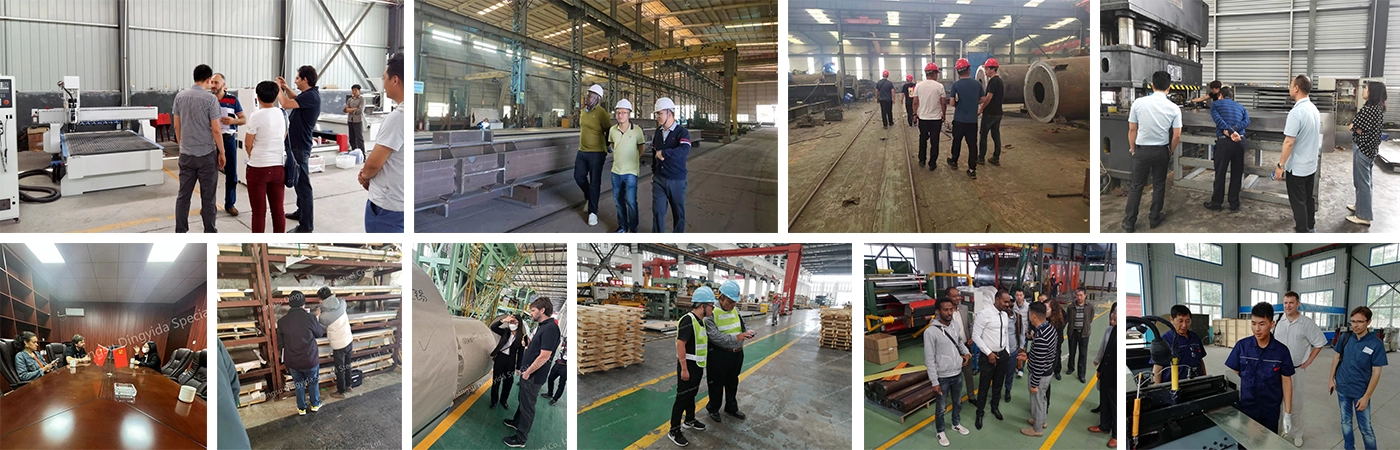

FACTORY

CUSTOMER VISIT

Customer communication

Partner

COMMON PROBLEM

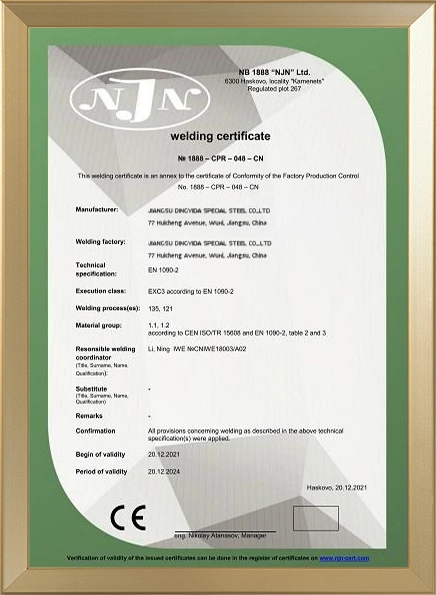

OUR HONOR

APPLICATION SCENARIOS

Oil field

Aircraft manufacturing

Train manufacturing

Ship manufacturing

Power industry

Construction industry

GET A FREE QUOTE

RELATED PRODUCTS