API Spec 5L Pipeline Steel Coil Steel Plate

Category:

Carbon Steel Plate

Chat with us now for a quick response.

Get expert sales advice within 12 hours.

Keyword:

API Spec 5L Pipeline Steel Coil Steel Plate

PRODUCT DETAILS

API Spec 5L Pipeline Steel Coil Steel Plate Description

API Spec 5L is an international standard that specifies the manufacturing requirements for two product specification grades (PSL 1 and PSL 2) of seamless and welded steel pipes used in pipeline transportation systems in the oil and gas industry.

Product Parameters

|

Product Name |

API Spec 5L Pipeline Steel Coil Steel Plate |

|

Production Process |

Hot Rolling, Cold Rolling |

|

Material Standards |

AISI, ASTM, ASME, DIN, BS, EN, ISO, JIS, GOST, SAE, etc. |

|

Width |

100mm-3000mm |

|

Length |

1m-12m, or Customized Size |

|

Thickness |

0.1mm-400mm |

|

Delivery Conditions |

Rolling, Annealing, Quenching, Tempered or Standard |

|

Surface Process |

Ordinary, Wire Drawing, Laminated Film |

Chemical Composition

|

API Spec 5L PSL1 |

Brand |

C |

Mn |

P |

S |

|

B |

≤ 0.28 |

≤ 1.20 |

≤ 0.030 |

≤ 0.030 |

|

|

X42 |

≤ 0.28 |

≤ 1.30 |

≤ 0.030 |

≤ 0.030 |

|

|

X46 |

≤ 0.28 |

≤ 1.40 |

≤ 0.030 |

≤ 0.030 |

|

|

X52 |

≤ 0.28 |

≤ 1.40 |

≤ 0.030 |

≤ 0.030 |

|

|

API Spec 5L PSL2 |

B |

≤ 0.24 |

≤ 1.20 |

≤ 0.025 |

≤ 0.015 |

|

X42 |

≤ 0.24 |

≤ 1.30 |

≤ 0.025 |

≤ 0.015 |

|

|

X46 |

≤ 0.24 |

≤ 1.40 |

≤ 0.025 |

≤ 0.015 |

|

|

X52 |

≤ 0.24 |

≤ 1.40 |

≤ 0.025 |

≤ 0.015 |

Mechanical Properties

|

Standard |

Brand |

Yield Strength(MPa) |

Tensile Strength(MPa) |

|

API Spec 5L PSL1 |

A25 |

172 |

310 |

|

A |

207 |

331 |

|

|

B |

241 |

414 |

|

|

X42 |

290 |

414 |

|

|

X46 |

317 |

434 |

|

|

X52 |

359 |

455 |

|

|

X56 |

386 |

490 |

|

|

X60 |

414 |

517 |

|

|

X65 |

448 |

531 |

|

|

X70 |

483 |

565 |

|

|

API Spec 5L PSL2

|

B |

290-496 |

414-758 |

|

X42 |

317-524 |

434-758 |

|

|

X46 |

359-531 |

455-758 |

|

|

X52 |

386-544 |

490-758 |

|

|

X56 |

414-565 |

517-758 |

|

|

X60 |

448-600 |

531-758 |

|

|

X65 |

483-621 |

565-758 |

|

|

X70 |

552-690 |

621-827 |

Scope of Application

API Spec 5L specifies the manufacture of two product levels (PSL1 and PSL2). PSL refers to the product specification level established for the API 5L standard. Piping specification classes are classified into PSL1 and PSL2. For pipeline standards, PSL1 and PSL2 pipelines have different levels of quality requirements. API Spec 5L pipeline steel plate is used to manufacture pipeline steel pipes that extract oil, steam, and water on the ground in the oil and gas industry.

Equivalent Material

|

Materials No. |

European Standard EN 10208-2 |

German Standard DIN 17172 |

API 5L |

|

1.0457 |

L 245NB |

You are 240.7 |

Gr.B |

|

1.0484 |

L 290NB |

You are 290.7 |

X42 |

|

1.0582 |

L 360NB |

StE 360.7 |

X52 |

|

1.8972 |

L 415NB |

You are 415.7 |

X60 |

|

1.0418 |

L 245MB |

You are 240.7 TM |

Gr.B |

|

1.0429 |

L 290MB |

You are 290.7 TM |

X42 |

|

1.0578 |

L 360MB |

You are 360.7 TM |

X52 |

|

1.8973 |

L 415MB |

You are 415.7 TM |

X60 |

|

1.8975 |

L 450MB |

You are 445.7 TM |

X65 |

|

1.8977 |

L 485MB |

You are 480.7 TM |

X70 |

| China | USA | Germany | Japan | France | U.K. | internationality |

|

GB3077 |

AlSI |

DIN |

JIS |

NE |

BS |

ISO |

|

20Mn2 |

1320 1221 |

20Mn5 |

SMn21 |

20M5 |

150M19 |

- |

|

30Mn2 |

1330 |

30Mn5 |

SMn24 |

32M5 |

150M28 |

- |

|

35Mn2 |

1335 |

36Mn5 |

SMnl |

35M5 |

150M36 |

- |

|

40Mn2 |

1340 1341 |

- |

SMn2 |

40M5 |

- |

- |

|

45Mn2 |

1345 |

46Mn7 |

SMn3 |

45M5 |

- |

- |

|

50Mn2 |

1052 |

50Mn7 |

- |

55M5 |

- |

- |

|

20MnV |

- |

20MnV6 |

- |

|

- |

- |

|

30Mn2MoW |

- |

-- |

- |

|

- |

- |

|

27SiMn |

- |

27MnSi5 |

- |

|

- |

- |

|

35SiMn |

- |

37MnSi5 |

- |

38MS5 |

- |

- |

|

42SiMn |

- |

38MnSi4 46MnSi4 |

- |

38MS5 |

- |

- |

|

20SiMn2MoV |

- |

- |

- |

- |

- |

- |

|

25SiMn2MoV |

- |

- |

- |

- |

- |

- |

|

37SiMn2MoV |

- |

- |

- |

- |

- |

- |

|

40B |

14B35 |

35B2 |

- |

- |

- |

- |

|

45B |

50B46H |

45B2 |

- |

- |

- |

- |

|

50B |

14B50 |

- |

- |

- |

- |

- |

|

4OM∏B |

15B41 |

- |

- |

- |

- |

- |

|

45MnB |

15B48 50B44 |

- |

- |

- |

- |

- |

|

20Mn2B |

- |

- |

- |

- |

- |

- |

|

20MnMoB |

80B20 |

- |

- |

- |

- |

- |

|

15MnVB |

- |

- |

- |

- |

- |

- |

|

- |

- |

- |

- |

- |

- |

- |

|

- |

- |

- |

- |

- |

- |

- |

|

20MnVB |

- |

- |

- |

- |

- |

- |

|

40MnVB |

- |

- |

- |

- |

- |

- |

|

20MnTiB |

- |

- |

- |

- |

- |

- |

|

25MnTiBRE |

- |

- |

- |

- |

- |

- |

|

2OSiMnVB |

- |

- |

- |

- |

- |

- |

|

15Cr |

5015 5115 |

15Cr3 |

SCr21 |

12C3 |

523A14 523M15 |

- |

|

15CrA |

- |

- |

- |

- |

- |

- |

|

20Cr |

5120 |

20Cr4 |

SCr22 |

18C3 18C4 |

527A19 527M20 |

683/11 20Cr4 20CrS4 |

|

30Cr |

5130 |

28Cr4 |

SCr2 |

28C4 32C4 |

530A30 530A32 |

- |

|

35Cr |

5135 |

34Cr4 37Cr4 |

SCr3 |

38C4 |

530A36 |

683/8 3、 3a、 3b |

|

40Cr |

5140 |

38Cr4 41Cr4 |

SCr4 |

42C4 |

530A40 530M40 |

683/1 4、 4a^ 4b |

|

45Cr |

5145 |

42Cr4 |

SCR5 |

45C4 |

- |

- |

|

50Cr |

5150 5152 |

- |

- |

50C4 |

En48 |

- |

|

38CrSi |

- |

- |

- |

- |

- |

- |

|

12CrMo |

4119 |

13CrMo44 |

- |

12CD4 15CD2 |

- |

- |

|

15CrMo |

ASTM A-387Gr. B |

15CrMo5 16CrMo44 |

SCM21 |

15CD4. 05 |

BS1653 |

- |

|

20CrMo |

4118 |

20CrMo5 22CrMo4 |

SCM22 |

18CD4 20CD4 |

CDS 12 CDSllO |

- |

|

30CrMo |

4130 |

25CrMo4 |

SCM2 |

30CD4 |

CDS 13 |

- |

|

30CrMoA |

- |

32CrMol2 3ICRMo12 |

- |

- |

- |

- |

|

35CrMo |

4135 4137 |

34CrMo4 35CrMo4 |

SCM3 |

35CD4 |

78A37 |

683/1 C35ea C35eb |

|

42CrMo |

4140 4142 |

41CrMo4 42CrMo4 |

SCM4 |

40CD4 42CD4 |

708M40 708A42 709M40 |

683/1 3 |

|

12CrMoV |

- |

- |

- |

- |

- |

- |

|

35CrMoV |

- |

35CrMoV5 |

- |

- |

- |

- |

|

12CrlMoV |

- |

13CrMoV4.2 |

- |

- |

- |

- |

|

25Cr2MoVA |

- |

24CrMoV5.5 |

- |

- |

- |

- |

|

25Cr2MolVA |

- |

- |

- |

- |

- |

- |

|

20CR3MoWVA |

- |

21CrVMoW12 |

- |

- |

- |

- |

|

38CrMoΛl |

6370 (ΛMS) |

34CrAlMo5 41CrAlMo7 |

SACM645 |

40CAD6.12 |

905M39 |

683/10 41CrAlMo74 |

|

20CrV |

6120 |

22CrV4 |

- |

22CrV4 |

- |

- |

|

40CrV |

6140 |

42CrV |

- |

42CrV4 |

- |

- |

|

50CrVA |

6150 |

50CrV4 |

SUPlO |

50CV4 |

735A50 |

- |

|

15CrMn |

- |

16MnCr5 |

- |

16MC5 |

- |

- |

|

20CrMn |

5120 |

20MnCr5 |

SMC21 |

20MC5 |

- |

- |

|

40CrMn |

5140 |

- |

SMC3 |

- |

- |

- |

|

20CrMnSi |

- |

- |

|

- |

- |

- |

|

25CrMnSi |

- |

- |

SMKl |

- |

- |

- |

|

30CrMnSi |

- |

- |

- |

- |

- |

- |

|

30CrMnSiA |

- |

- |

- |

- |

- |

- |

|

35CrMnSiA |

- |

- |

SMK2 |

- |

- |

- |

|

20CrMnMo |

4119 |

20CrMo5 |

SCM23 |

- |

- |

- |

|

40CrMnMo |

4140 |

- |

- |

- |

- |

- |

|

20CrMnTi |

- |

- |

SMK22 |

- |

- |

- |

|

30CrMnTi |

- |

30MnCrTi4 |

- |

- |

- |

- |

|

20CrNi |

3120 |

20NiCr6 |

- |

20NC6 |

637A16 637M17 |

- |

|

40CrNi |

3140 |

46NiCr6 |

SNCl |

35NC6 |

640A35 640M40 |

- |

|

45CrNi |

3145 |

45NiCr6 |

- |

- |

- |

- |

|

50CrNi |

3150 |

- |

- |

- |

- |

- |

|

12CrNi2 |

3115 |

14NiCrlO |

SNC21 |

IONCll 14NC11 |

- |

- |

|

12CrNi3 |

3310 |

13NiCrl2 |

SNC22 |

10NC12 14NC12 |

655A12 655M13 |

- |

|

20CrNi3 |

- |

22NiCrl4 |

- |

20NC11 |

- |

- |

|

30CrNi3 |

- |

28NiCrlO 31NiCrl4 |

SNC2 |

30NC11 30NC12 |

- |

- |

|

37CrNi3 |

- |

35NiCrl8 |

SNC3 |

35NC15 |

- |

- |

|

12Cr2Ni4 |

E3310 |

14NiCrl8 |

- |

12NC15 |

- |

- |

|

20Cr2Ni4 |

E3316 |

22NiCrl4 |

- |

20NC14 |

659A15 659M15 |

- |

|

20CrNiMo |

8620 8720 |

20NiCrMo2 21NiCrMo2 |

- |

20NCD2 |

805A20 805M20 |

- |

|

40CrNiMoA |

4340 9840 |

36NiCrMo4 40NiCrMo6 |

SNCM8 |

35NCD5 40NCD3 |

817M40 816M40 |

- |

|

45CrNiMoVA |

4437 |

- |

SNCM9 |

- |

- |

- |

|

18Cr2Ni4WA |

|

|

|

|

|

|

|

25Cr2Ni4WA |

|

|

|

|

|

|

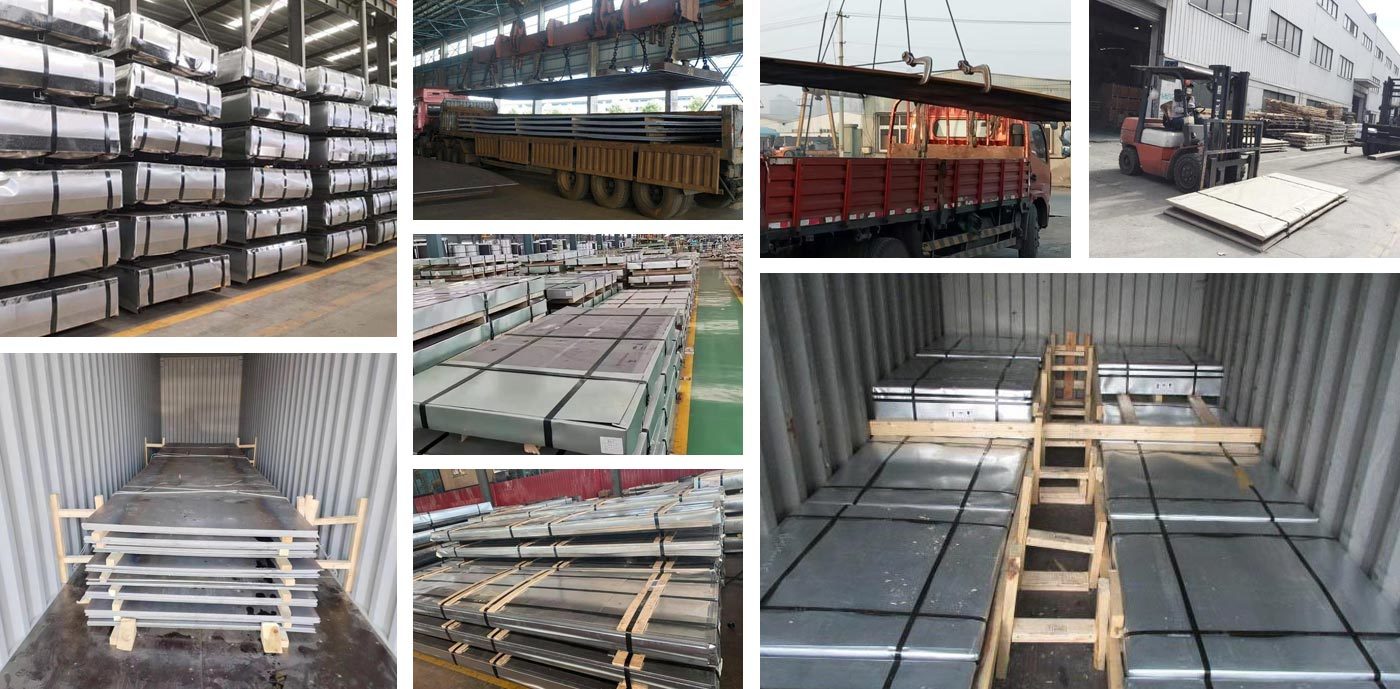

Packing and delivery

Our annual sales are 8,000 tons. It is the top steel service provider and steel solution provider in the region. The company has a powerful sales team to provide customers with comprehensive technical support, pre -sales service and comprehensive after -sales service. The entire perfect treatment and sales process is our quality assurance.

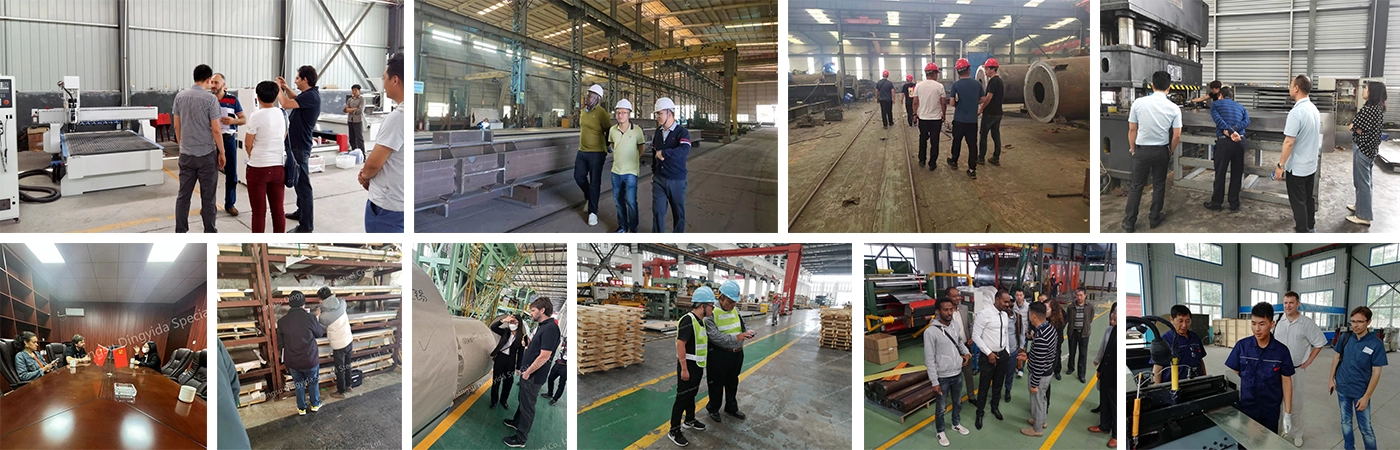

FACTORY

CUSTOMER VISIT

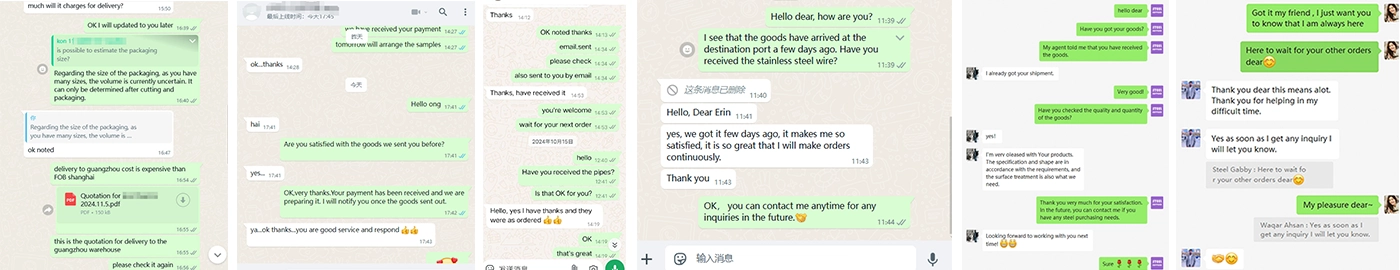

Customer communication

Partner

COMMON PROBLEM

OUR HONOR

APPLICATION SCENARIOS

Oil field

Aircraft manufacturing

Train manufacturing

Ship manufacturing

Power industry

Construction industry

GET A FREE QUOTE

RELATED PRODUCTS