Monel Alloy Bar

Category:

Monel Alloy

Chat with us now for a quick response.

Get expert sales advice within 12 hours.

Keyword:

Monel Alloy Bar

PRODUCT DETAILS

Equivalent grade |

UNS N04400 |

DIN W. Nr. 2.4360, 2.4361 |

Title : Monel400/UNS N04400 |

Available products: plate/sheet, bar/rod, pipe/tube, strip, fittings, wire, forging, fastener, customization

Production standards | |

Product | ASTM |

Bar and wire | B 164 |

Sheets, Sheets and Strips | B 127, B 906 |

Seamless pipes and fittings | B 165, B 829 |

Welded pipe | B 725, B 775 |

Welded fittings | B 730, B 751 |

Solder connection | B 366 |

Forging | B 564 |

Chemical composition

% | Ni | Cu | Fe | C | Mn | Si | S |

Min | 63.0 | 28.0 |

|

|

|

|

|

Max |

| 34.0 | 2.5 | 0.30 | 2.00 | 0.50 | 0.024 |

Physical properties

Density | 8.8g/cm3 |

Melting | 1300-1350℃ |

Monel 400 Material Properties

The chemical composition of the alloy is mainly composed of 30% Cu and 65% Ni with a small amount of Fe (1%-2%). Due to the difference in chemical composition, it can have a variety of alloy grades, but there is no significant difference in corrosion resistance between them. Monel400 alloy is more resistant to corrosion by reducing media than pure nickel, and more resistant to corrosion by oxidative media than pure copper. Monel400 is a deformable nickel-copper-based nickel-based alloy with good seawater corrosion resistance and chemical corrosion resistance, as well as chloride stress corrosion cracking resistance. This alloy is one of the few alloys that can be used in fluoride. It has good resistance to oxide stress fission corrosion in hydrofluoric acid and fluorine gas media, such as seawater and saltwater environments.

Advantage

1. Outstanding corrosion resistance in diverse environments.

2. High tensile strength and toughness at elevated temperatures.

3. Easy formability, machining, and welding due to ductility.

4. Low permeability to hydrogen gas for gas-tight applications.

5. Resistance to erosion and cavitation damage in high-velocity flows.

6. Retains mechanical properties across wide temperature ranges.

7. Long service life, reducing maintenance costs over time.

8. Versatile applications across marine, chemical, aerospace, and more.

Application areas of Monel 400 material

Monel 400 is mainly used in chemical and petrochemical and marine development fields. It can be used to manufacture various heat exchange equipment, boiler feed water heaters, petroleum and chemical pipelines, vessels, towers, tanks, valves, pumps, reactors, shafts, etc. Marine heat exchangers, desalination equipment, salt production equipment, marine and chemical processing equipment, propeller shafts and pumps, gasoline and water tanks, etc.

Chinese Monel 400 round bar is a high-quality product with excellent performance.

Monel 400 is known for its outstanding corrosion resistance, especially in harsh environments such as seawater and acidic conditions. The Chinese-produced Monel 400 round bar maintains these superior properties.

It has good mechanical strength and ductility, enabling it to be used in various industrial applications. The round bar shape provides convenience in processing and installation.

This product is manufactured with strict quality control to ensure its reliability and durability. It is suitable for a wide range of industries, including marine, chemical, and petrochemical.

Whether for construction, equipment manufacturing, or other engineering projects, the Chinese Monel 400 round bar offers a reliable and efficient solution. It is a testament to the advanced manufacturing capabilities of the Chinese industry in producing high-quality alloy products.

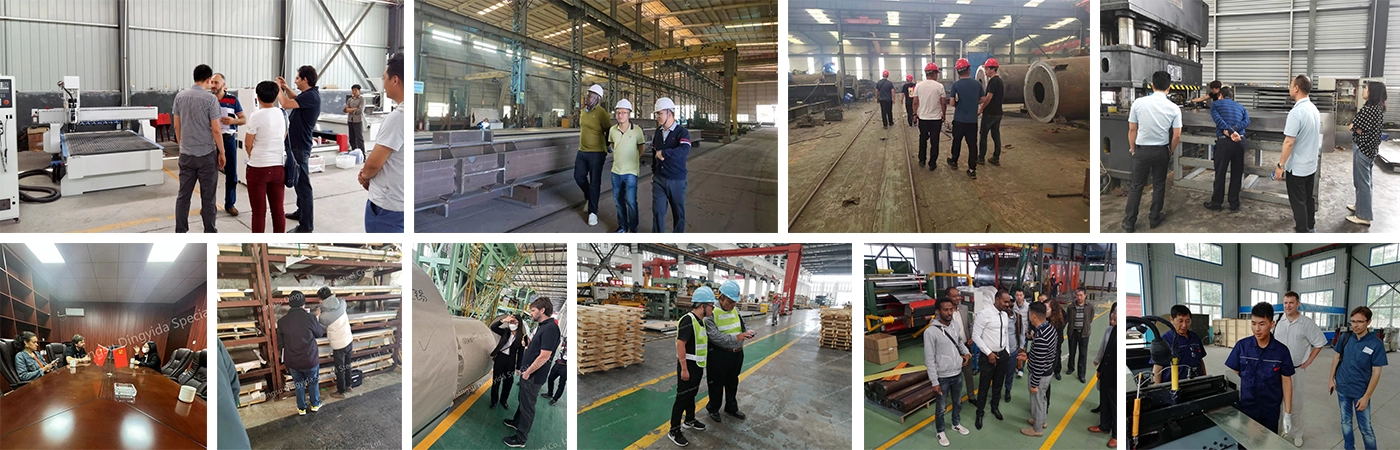

FACTORY

CUSTOMER VISIT

Customer communication

Partner

COMMON PROBLEM

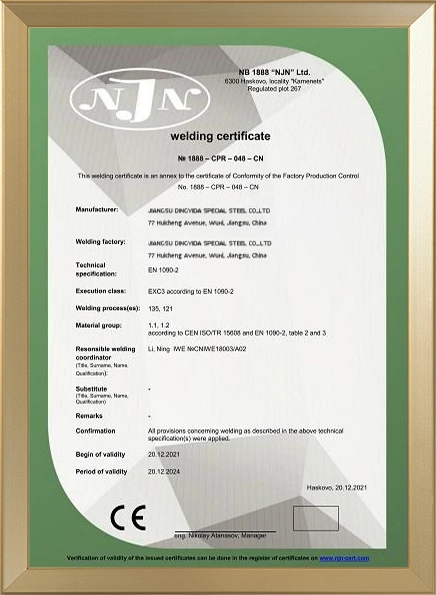

OUR HONOR

APPLICATION SCENARIOS

Oil field

Aircraft manufacturing

Train manufacturing

Ship manufacturing

Power industry

Construction industry

GET A FREE QUOTE

RELATED PRODUCTS