Inconel Alloy Coil

Category:

Inconel Alloy

Chat with us now for a quick response.

Get expert sales advice within 12 hours.

Keyword:

Inconel Alloy Coil

PRODUCT DETAILS

Equivalent grade |

UNS N06617 |

DIN W. Nr. 2.4663A |

Available products:plate/sheet, bar/rod, pipe/tube, strip, fittings, wire, forging, fastener, customization

Production standards | |

Product | ASTM |

Bar, Fastener and Wire | B 166 |

Plate, Sheet and Strip | B 168, B 906 |

Seamless pipe,tube | B 167, B 829 |

Welded pipe | B 517, B 775 |

Weld tube | B 516, B 751 |

Welded pipe fittings | B 366 |

Billets and billets for forging | B 472 |

Forging | B 564 |

Chemical composition

% | Ni | Cr | Co | Mo | Fe | C | Mn | Si | S | Al | Ti | Cu | B |

Min | 44.5 | 20.0 | 10.0 | 8.0 |

| 0.05 |

|

|

| 0.80 |

|

|

|

Max |

| 24.0 | 15.0 | 10.0 | 3.0 | 0.15 | 1.00 | 1.00 | 0.015 | 1.50 | 0.60 | 0.50 | 0.006 |

Physical properties

density | 8.36 g/cm3 |

Melting | 1330-1375℃ |

tensile strength (σb) | ≥655 Mpa |

yield point (σs) | ≥241 Mpa |

elongation (δ) | ≥35% |

Inconel 617 Features

The alloy has excellent corrosion resistance and creep properties in hot corrosion areas such as sulfurized environments, especially in oxidizing and carbonizing environments up to 1100°C cycles. These corrosion resistances combined with excellent mechanical properties make this alloy particularly suitable for high temperature applications. Good short-term and long-term mechanical properties at high temperatures up to 1100°C. Excellent carburization resistance and good weldability at high temperatures up to 1100°C.

Inconel 617 is particularly suitable where high temperatures and particularly high mechanical stress are present. This alloy is recommended for operating temperatures up to 1000°C. Inconel617 can manufacture thin wall parts.

Alloy617 products are commonly used in gas turbine combustion tanks and conduits, heat treatment equipment, petrochemical processing, power plant equipment, nitric acid production accessories, etc.

Advantage

1. High temperature strength and oxidation resistance.

2. Excellent resistance to carburization and sulfidation.

3. Good mechanical properties at elevated temperatures.

4. Resistance to chloride stress-corrosion cracking.

5. High creep rupture strength.

6. Suitable for high-temperature applications in aerospace, chemical processing, and power generation industries.

Typical application areas for Inconel617 include

1.Components of industrial and aviation gas turbines such as combustion cans, casings, turbine rings and other components exposed to high temperatures,

2.Air heaters, muffles and radiant pavilions

3.High temperature heat exchangers, valves and springs,

4.High temperature gas-cooled nuclear reactors, such as nuclear reactor high temperature components - helium/helium medium heat exchanger

5.Chemical equipment, spiral pipes and pipes in the petrochemical industry, etc.

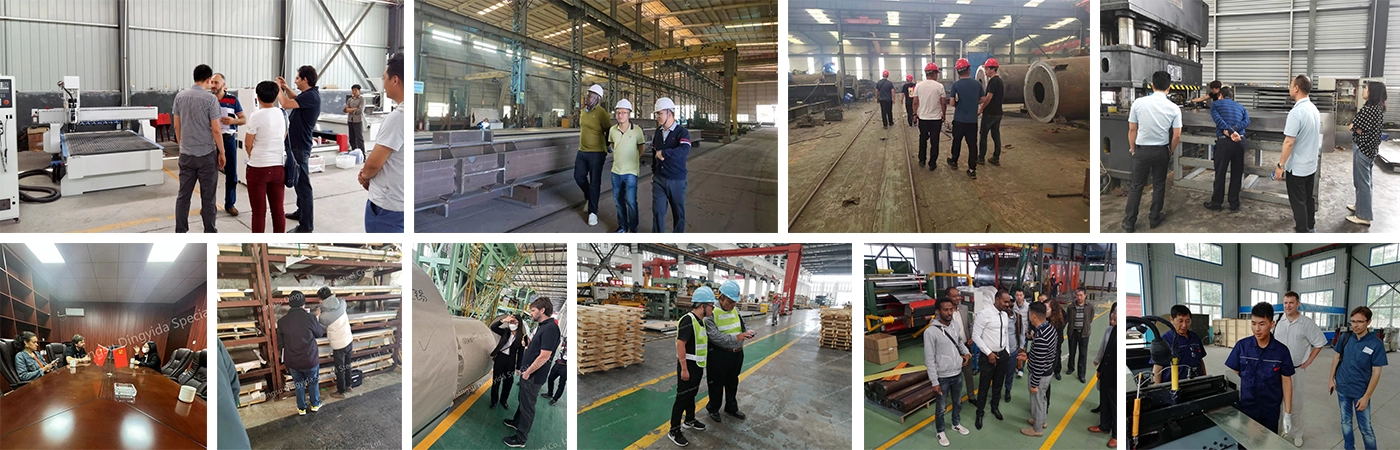

FACTORY

CUSTOMER VISIT

Customer communication

Partner

COMMON PROBLEM

OUR HONOR

APPLICATION SCENARIOS

Oil field

Aircraft manufacturing

Train manufacturing

Ship manufacturing

Power industry

Construction industry

GET A FREE QUOTE

RELATED PRODUCTS