Inconel Alloy Bar

Category:

Inconel Alloy

Chat with us now for a quick response.

Get expert sales advice within 12 hours.

Keyword:

Inconel Alloy Bar

PRODUCT DETAILS

Equivalent grade |

UNS N06600 |

DIN W. Nr. 2.4816 |

Available products: plate/sheet, bar/rod, pipe/tube, strip, fittings, wire, forging, fastener, customization

Production standards | |

Product | ASTM |

Bar and wire | B 166 |

Plate, Sheet and Strip | B 168, B 906 |

Seamless pipe,tube | B 167, B 829 |

Welded pipe | B 517, B 775 |

Weld tube | B 516, B 751 |

Welded pipe fittings | B 366 |

Billets and billets for forging | B 472 |

Forging | B 564 |

Fastener | F2281 |

Chemical composition

% | Ni | Cr | Fe | C | Mn | Si | S | Cu |

Min | 72.0 | 14.0 | 6.0 |

|

|

|

|

|

Max |

| 17.0 | 10.0 | 0.15 | 1.00 | 0.50 | 0.015 | 0.50 |

Physical properties

Density | 8.47 g/cm3 |

Melting | 1354-1413℃ |

Inconel 600 Features

Inconel 600 is both corrosion and high temperature resistant, strong and easy to process. Resists chloride ion stress corrosion cracking, sulfide and oxidizing media in high temperature environments. It has good corrosion resistance in organic acids such as formic acid, acetic acid and stearic acid, and moderate corrosion resistance in inorganic acids. Excellent corrosion resistance in high-purity water used in primary and secondary cycles in nuclear reactors. Particularly outstanding performance is the ability to resist the corrosion of dry chlorine and hydrogen chloride, and the application temperature is up to 650 ℃. At high temperature, Inconel 600 in the annealed and solution treated state has good oxidation spalling resistance and high strength in air.

Advantages of Inconel 600

1. High strength

2. Excellent corrosion resistance, particularly in harsh environments

3. Superior performance at elevated temperatures

4. Outstanding oxidation resistance, suitable for oxidative environments

5. Good machinability, facilitating fabrication processes

6. Versatile application across various industries

Application

Chemical production, retorts and components in heat treatment furnaces, aircraft fuselage components, nuclear reactors.

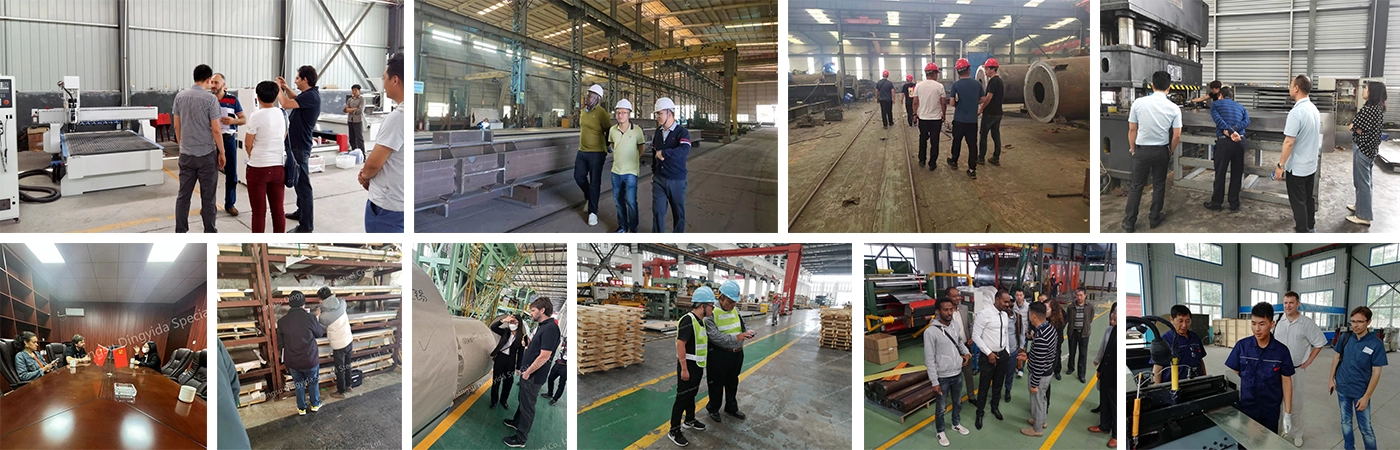

FACTORY

CUSTOMER VISIT

Customer communication

Partner

COMMON PROBLEM

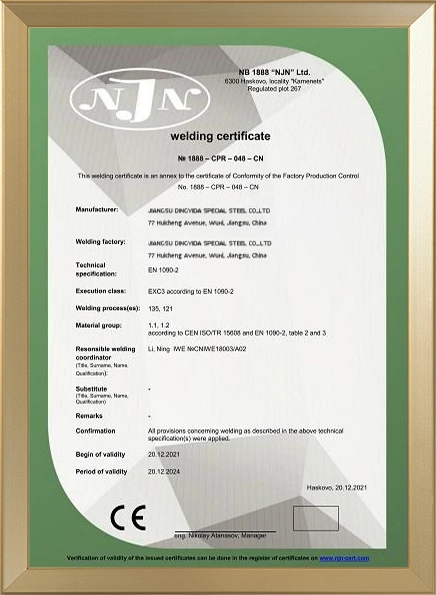

OUR HONOR

APPLICATION SCENARIOS

Oil field

Aircraft manufacturing

Train manufacturing

Ship manufacturing

Power industry

Construction industry

GET A FREE QUOTE

RELATED PRODUCTS