Hastelloy Alloy Coil

Category:

Hastelloy Alloy

Chat with us now for a quick response.

Get expert sales advice within 12 hours.

Keyword:

Hastelloy Alloy Coil

PRODUCT DETAILS

Equivalent grade |

UNS N06635 |

Title:Hastelloy S/ UNS N06635 |

Available products: plate/sheet, bar/rod, pipe/tube, strip, fittings, wire, forging, fastener, customization

Products | ASTM |

Pipe | B 619, B 622 |

Plate, Sheet, and Strip | B 333, B 575 |

Fittings | B 366 |

Forgings | B 564, B 462 |

Chemical composition

% | Ni | Cr | Mo | Fe | W | Co | Al | Mn | C | Si |

Min | 67 |

16 |

15 |

|

|

|

|

|

| 0.4 |

Max |

| 3 | 1 | 2 | 0.25 | 0.5 | 0.02 |

Physical properties

density | 8.75 g/cm3 |

Melting | 1335-1380℃ |

Introduction

Hastelloy S is a nickel-based superalloy known for its exceptional resistance to a wide range of corrosive environments, particularly in oxidizing and reducing conditions. This alloy contains significant amounts of nickel, chromium, molybdenum, and tungsten, which contribute to its outstanding corrosion resistance and high-temperature strength. Hastelloy S is designed to withstand aggressive chemical environments, making it suitable for applications in chemical processing, petrochemical, and power generation industries.

Key features of Hastelloy S include excellent resistance to sulfuric acid, phosphoric acid, hydrochloric acid, and other acidic solutions, as well as resistance to oxidizing and reducing media. It exhibits good mechanical properties even at elevated temperatures, allowing it to maintain integrity in demanding operating conditions.

Hastelloy S is commonly used in components such as reactors, heat exchangers, valves, and piping systems where corrosion resistance and reliability are critical. Its versatility and proven performance make it a preferred material for applications requiring exceptional resistance to corrosion and high-temperature environments.

Advantages of Hastelloy S

1. Superior corrosion resistance in various aggressive environments.

2. High-temperature strength ensures structural integrity in demanding conditions.

3. Versatile applicability across different industrial sectors and applications.

4. Excellent resistance to sulfuric acid for specialized applications.

5. Reliable resistance to phosphoric acid, ideal for specific industries.

6. Good weldability facilitates ease of fabrication and installation.

7. Long-term reliability in aggressive and high-temperature environments.

8. Proven track record instills trust in critical applications.

Hastelloy S application

Hastelloy S finds extensive application across industries requiring exceptional corrosion resistance and high-temperature performance. Commonly used in chemical processing, petrochemical, and power generation industries, it is employed in reactors, heat exchangers, and piping systems exposed to aggressive chemicals and elevated temperatures. Additionally, Hastelloy S is utilized in the pharmaceutical and fertilizer industries for equipment involved in production processes. Its versatility and reliability make it indispensable for critical applications where durability and corrosion resistance are paramount.

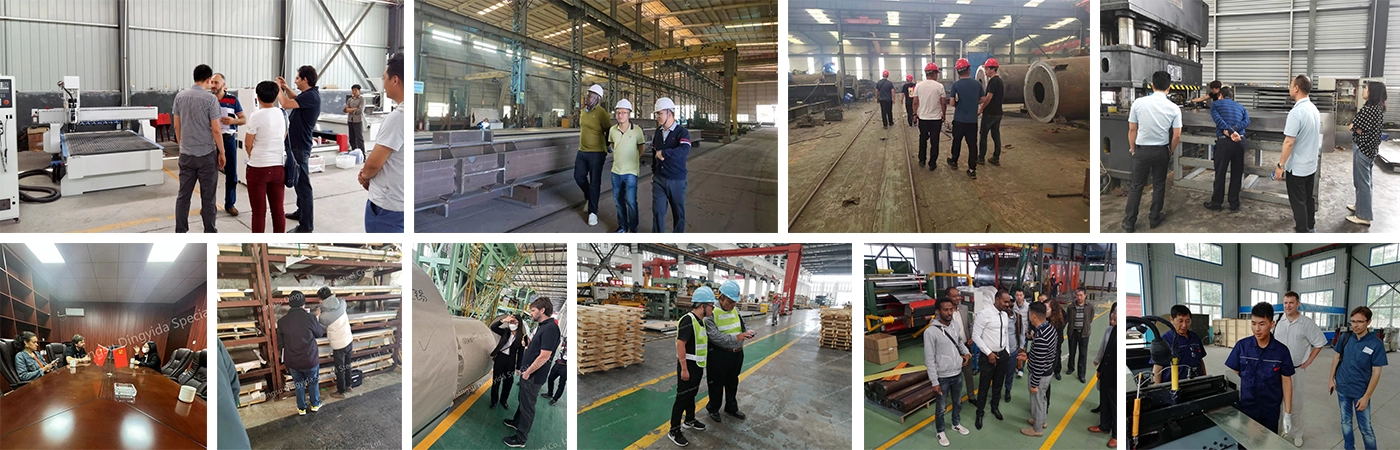

FACTORY

CUSTOMER VISIT

Customer communication

Partner

COMMON PROBLEM

OUR HONOR

APPLICATION SCENARIOS

Oil field

Aircraft manufacturing

Train manufacturing

Ship manufacturing

Power industry

Construction industry

GET A FREE QUOTE

RELATED PRODUCTS